Plan C: What now?

So, what now?

Yes, a very good question! Let me try to answer it.

Warning: This may be a little technical and boring.

Let’s call this PLAN C.

1) By now you know the reason for the hard right hand turn to get to Walvis Bay was triggered by the failure of the main solar panels, on the aft deck, to charge the batteries.

When I was doing my research on what was the most common issues on ocean rowing boats (very few kayaks that have crossed an ocean) a thread that repeated itself was the lack of power from the batteries for a variety of reasons.

The power issues are almost always a knock-on effect of too little charge from the PV panel from a fault or corrosion, like I have, or too little sun light or just not enough solar panels for the boats power consumption.

We had to redesign the back deck of Osiyeza to take the massive panels. I did not want to be in a situation as described above. I have 470Watts of PV Panels which is a LOT. I also chose the best flexible marine panels in the market and imported them from Italy. The Super Rugged Solbian panels are completely waterproof and tough enough to walk on. They are glued to the back deck with pre attached 3M peel and stick.

The wiring runs inside a watertight buoyancy box. Basically, the top half of the back deck, so “should” have no contact with sea water. The wire connectors are also waterproof so if water does get in then it should still not be a problem.

For them to fail means that both defences have been breached.

We know water got into the sealed buoyancy box. The second defence breach I am yet to identify. Is it the connectors or the panel junction box?

To access the wires an inspection hole will need to be cut into the side of Osiyeza that is big enough to get hands and equipment inside. Then it’s to identify where the leak is and seal it. Once that’s completed the inspection hole that was cut out needs to be bonded back in place making sure that the hull is still structured sound.

And that’s if it’s not a problem with a panel. In that case I would have to remove the faulty panel and find a replacement. Not a small job and let’s not forget Osiyeza is constructed out of carbon fibre so a little more skill and material is required.

2) From discussions over the past two days with several experts it seems the autopilot system will need to be redesigned, manufactured, installed, and tested. Not a small project.

The autopilot cable inside Osiyeza.

The autopilot cable inside Osiyeza.

3) A solution to stopping the air that is being sucked in through the water maker intake needs to be found. With Osiyeza being so light the water intake is only 200mm below the waterline and with all the rocking and rolling air bubbles get sucked in along with the water. I did install a small sea chest to remove the air bubbles but 200mm is just not enough height for it to work in anything other than flat water.

4) The solution to the chart plotter GPS signal is to find and install an external antenna.

Chartplotter hanging by strings to get better GPS signal.

Chartplotter hanging by strings to get better GPS signal.

5) The rudder had a loud knocking noise which I think is the movement between the pin and bush. How serious an issue this is I don’t know but it needs to be looked at.

6) My floating bridle is cunning design but a practical failure. It needs to be redesigned.

7) The seat is super comfy, but it’s not made to be used 24/7. I need to find someone who can make up a new cover.

8) The canard cover was ripped off while on sea anchor. This needs to be replaced and hopefully the modified bridle system will avoid a repeat.

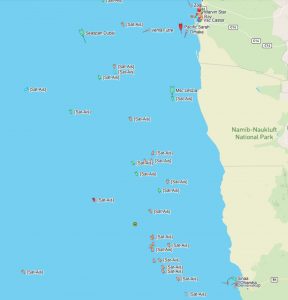

With all these items to attend to we have made the call to get Osiyeza back to Cape Town where the marine industry is best equipped to assist. We hope to have her on a truck and in Cape Town this weekend. I plan to fly back on Friday after loading Osiyeza onto the truck.

Hopefully it’s a quick turn around with no major hiccups.

Plan D

Right now, is to get Osiyeza back to Walvis Bay ASAP to continue the crossing to Salvador.

Fingers crossed 🤞🤞🤞🤞🤞🤞🤞

No of smiles changed: 20. Thank you to everyone who has donated.